Benefits And Limitation Of DDGS For Swine

Pigs do not require corn and soybean meal (SBM); they require energy, amino acids, and other nutrients in adequate available amounts for normal growth. It is just in most cases that corn-SBM diets provide the closest match to the pig’s requirements at the lowest cost. However, there has been a very rapid growth of the ethanol industry in the United States and other countries as well, which has resulted in an increasing amount of ethanol co-products available for livestock feed. The three main co-products of the ethanol industry are Distillers Grains, Solubles, and Distillers Grains with Solubles (DDGS), and they can be either “wet” or “dried” depending on the manufacturing process. DDGS contains the same or slightly higher energy levels than corn, but it contains approximately 27% protein so most people consider it a protein source. Since on-farm feed mixing and swine feeding systems are almost exclusively designed for dry feed and DDGS is the only form that is exported, this paper will focus only on Distillers Dried Grains with Solubles (DDGS) as an alternate protein source for swine.

DDGS

Corn is 2/3 starch and during the fermentation & distillation processes, the starch is converted to

ethanol. 25.5 kg of corn produces approximately 9.9 liters of ethanol, 7.7 kg of CO2, and a wet

spent-mash. This wet mash goes through a series of centrifuges, evaporators, and presses to produce

Solubles (liquid) and Distillers Grains (semi-dry). The Solubles and Distillers Grains are then blended

and dried to produce 7.7 kg of DDGS from the same 25.5 kg of corn.

DDGS is a co-product, and like all co-products (soybean meal, meat and bone meal, sunflower meal), it can vary greatly in nutrient concentrations. Ranges of nutrient concentrations and physical characteristics from nine DDGS samples (Cromwell et al., 1993) are shown below:

Dry matter 87 - 93%

Crude protein 23 - 29%

Crude fat 3 - 12%

Lysine .59 - .89%

Color light golden to dark brown

Smell sweet to smoky or burnt

Growth trials were also conducted using the nine different DDGS sources, and there were large differences in gain, feed intake, and feed efficiency depending on the source of DDGS in the diet. Therefore, DDGS quality has a considerable impact on livestock performance.

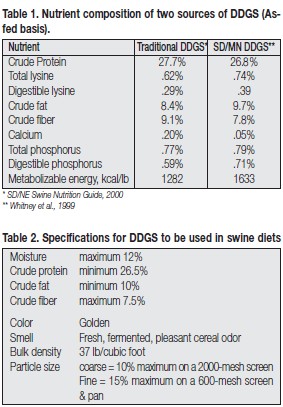

These differences in nutrient concentrations can occur for several reasons. First of all, there are differences in processing methods. Type of yeast used, fermenting & distillation efficiency, drying temperature and time, and amount of solubles blended with the dry material all affect the nutrient concentrations in DDGS. Laboratory analysis of 789 DDGS samples from May 2002 to April 2003 showed that crude protein levels ranged from 20.90 to 37.66% (Woerman, 2003). One way to explain some of this huge range is the type of ethanol plant. Recent research at the University of Minnesota (Whitney et al., 1999) has shown that DDGS from the new generation ethanol plants in SD and MN have higher nutrient concentrations than traditional ethanol plants. The following table shows the nutrient composition of traditional and “new generation” DDGS.

The second factor to have a major impact on DDGS nutrient concentrations is the nutrient variability of the corn used. Since the starch in corn is converted to ethanol and then removed, the remaining nutrients in corn are concentrated and roughly tripled in the resulting DDGS. For example, if a load of corn contains .26% lysine, the resulting DDGS will likely contain .78 % lysine. However, if a lower lysine corn (.23% lysine) is used, the resulting DDGS will contain only .69% lysine. The same rule applies for the concentrations of all the other nutrients (fat, fiber, protein, phosphorus, etc.) This can lead to a large within-plant variation of nutrients. For example, one “New” generation plant took 6 DDGS samples in 1998, and lysine levels from those six samples ranged from .65 to .97%, a 50% difference!

As just discussed, there is a large difference in nutrient concentrations between the processing method, especially for two of the most critical nutrients: digestible lysine (34.5%) and digestible phosphorus (20.3%). The question then becomes “What values do I use when formulating swine rations?” The best answer is to properly sample each load of DDGS you get and analyze for lysine and phosphorus. Then, multiply those values by their digestibility coefficients (lysine = .53; phosphorus = .90) to get the amount digestible of each nutrient. For example, if a sample of DDGS contained .80% total lysine and .78 total phosphorus, you’d multiply .80% times .53 to get a digestible lysine value of .42%. Then, multiply .78% by .90 to get a digestible phosphorus concentration of .702%. These are then the values you need to use when balancing swine rations.

If analyzing each load of DDGS is not feasible, the next best thing to do is to visit with the plant you’ve purchased the DDGS from and find out the nutrient range of their product over the last six months. To avoid a potential nutrient deficiency, it is then best to select a value at the lower end of each range to use when formulating. If that data is not available, consider changing suppliers or use the values for traditional DDGS.

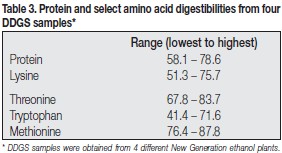

Another method to reduce nutrient variation is to develop a DDGS specification sheet for nutrient levels and physical characteristics, and then only buy DDGS from plants that will guarantee meeting those specifications. However, you are responsible for periodic testing to ensure your specifications are being met. Table 2 is one example of such a sheet.

Color can give a rough estimation of DDGS quality. In most cases, golden DDGS will be of high quality. However, just because a sample of DDGS is darker in color does not mean it is necessarily of poorer quality. While often times DDGS gets darker the more it is heated during the drying process (resulting in lower quality DDGS), it can also become darker when more syrup is added back to the Dried Distiller’s Grains, which is dictated by the price of syrup. The additional syrup will have no negative impact on DDGS quality, and may be equal to golden DDGS in feeding value.

Mycotoxins

Mycotoxins are produced by molds either in the field or during storage, and can severely impact pig

and sow performance. While there are many different mycotoxins, zearalenone and vomitoxin (DON)

are the main ones of concern for SD pork producers. Unfortunately, the fermentation process does

not destroy mycotoxins. In fact, just like lysine and other nutrients, it concentrates the mycotoxins

three-fold. If corn containing 1 ppm zearalenone is delivered to an ethanol plant, the resulting DDGS

will contain 3 ppm zearalenone. Since the maximum inclusion rate of both mycotoxins is 1 ppm in

the total diet, it does not take a large amount of mycotoxins to cause problems, especially for sows.

This is more of a problem if the ethanol plant is purchasing damaged grains or if it has been a year in which there has been a mycotoxin problem in the corn in the field.

Incorporating DDGS Into Swine Diets

Pigs require amino acids, not protein, so swine diets need to be balanced on a lysine or digestible

lysine basis, not on crude protein. While DDGS is relatively high in protein, it is still low in lysine, the

first limiting amino acid for swine in grain-based diets. Due to its poor amino acid balance for pigs,

corn is poor quality protein source for pigs. When corn is processed into DDGS, the poor amino acid

balance is concentrated, not improved in DDGS. For example, lysine makes up 6.4% of the protein

in SBM, but in DDGS, lysine makes up only 2.5% of the protein. Therefore, to properly incorporate

DDGS in swine diets, the diets must be formulated on a digestible lysine basis. If the diets are balanced

on crude protein, the diets will be grossly deficient in lysine and other essential amino acids, and pig

performance will be substantially decreased.

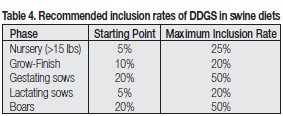

Another major factor to consider when incorporating DDGS into swine diets is that it has a much poorer amino acid digestibility than soybean meal. When comparing amino acid digestibilities of DDGS vs SBM, lysine (47 vs 85%), tryptophan (50 vs 81%), and threonine (55 vs 78%) digestibilities are significantly lower for DDGS than those from SBM. Therefore, when formulating diets with DDGS, you MUST use available amino acid values, not total amino acid levels, to meet the pig’s requirements due to DDGS’ lower amino acid digestibility when compared to SBM. If balancing on total lysine, then the maximum inclusion level is 10%. However, if the digestible lysine content of a DDGS load is known, then it can be included at a much higher concentration (>10%).

Also, there is also variation in amino acid digestibility between New Generation plants. Stein et al., (2004) looked at apparent ileal digestibility between four DDGS samples from New Generation plants. While the nutrient content of the four samples was similar, there was a large variation in protein and amino acid digestibility (Table 3). Therefore, it is critical that the DDGS source to build a data base on the amino acid (AA) digestibilities from that plant. The other option would be to be conservative and use the lower AA digestibility values. In doing this pig performance would not suffer. However, if using a higher quality DDGS, you would not be able to take advantage of the improved nutrient profile.

When using DDGS as an amino acid source, it is advisable to add synthetic lysine to the diets. This helps improve the amino acid balance and also reduces nitrogen excretion, a major environmental concern. To use higher levels of DDGS, you should consider adding other synthetic amino acids to the ration when economical.

It should be kept in mind that DDGS is not just another amino acid source. It is also an excellent source of digestible phosphorus. Therefore, when adding DDGS to a diet, you will be able to reduce the amount of dicalcium phosphate normally used.

Various trials have reported differing energy values for DDGS. While the energy values have ranged from slightly above to slightly below that of #2 yellow corn, in most cases it is safe to assume the DDGS from New Generation plants has a similar metabolizable energy concentration to corn.

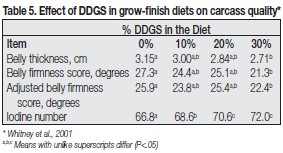

As was mentioned before, source of DDGS is critical on pig performance. The following recommendations (Table 4) are based on using a high quality DDGS, and that the diets are balance on digestible lysine and phosphorus.

It is recommended starting at the lower inclusion level, and then gradually work your way up to the maximum inclusion rate, especially for sows. Research at the University of Minnesota has shown that immediately going to the higher levels for sows resulted in an initial reduction in feed intake for about one week before they went back to full feed. Also, mycotoxins have the greatest effects on reproduction so extra care must be taken when using DDGS in sow diets.

DDGS concentrations up to 30% of the diet have no affect on grow-finish pig performance. However, the 30% inclusion level does result in carcasses that have reduced belly firmness and soft fat due to the high concentrations of polyunsaturated fatty acids in DDGS (Whitney, et al., 2001; Table 5). This was also observed by Thaler and Rops, 2003. Therefore, 20% is the maximum recommended amount in grow-finish diets.

Storage

DDGS contains approximately 10% fat, and a large portion of that fat is composed of polyunsaturated

fatty acids. Since polyunsaturated fatty acids are subject to rancidity, producers need to use DDGS

as quickly as possible. It is recommended that producers buy no more than three months supply of

DDGS in the winter, and no more than a one month supply in the summer. Due to its high fat content,

DDGS “flowability” through bulk bins may be a potential problem. Use caution when selecting the

facility to store DDGS in on-farm.

Health Benefits

There have been reports by producers that 10-20% DDGS in grow-finish diets reduces the

incidence/severity of ileitis and Hemorrhagic Bowel Syndrome (HBS). Research at the University of

Minnesota (Whitney et al., 2003) has shown that dietary additions of DDGS did lessen ileitis’ effect

on pig’s small intestines during an ileitis challenge. However, they observed no benefit in growth

performance, morbidity, or mortality. In a trial just completed at South Dakota State University (Thaler

et al., 2003), we saw no effect of either DDGS or soy hulls additions on pig performance during an

ileitis challenge. However, a commercially available antibiotic was effective in reducing the severity of

the disease challenge. Therefore, caution should be used when applying any economic value to DDGS’s

health effects. In fact, personal communications with practicing veterinarians have indicated that DDGS

appears to work approximately 50% of the time against ileitis in commercial swine operations.

Economics

DDGS provides lysine, phosphorus, and energy, and replaces soybean meal, dicalcium phosphate, and corn. When considering the economics of using DDGS, all these factors must be included. As a “Rule of Thumb”, 90.9 kg of DDGS and 1.36 kg of limestone can replace 80.9 kg of corn, 8.6 kg of 46% protein soybean meal, and 2.7 kg of dicalcium phosphate in a ton of complete feed. However, by balancing on a digestible amino acid basis and making certain all ten essential amino acid requirements are being met, higher concentrations of DDGS can be used in swine diets. For ease of calculation, there is an Excel spreadsheet available on the SDSU Dept. of Animal and Range Sciences homepage (https://ars.sdstate.edu/SwineExt/ddgs.htm).

If a producer has properly formulated diets with the DDGS concentrations not exceeding the maximum recommended levels, the decision to use DDGS depends on which complete diet is less expensive: corn-SBM or corn-SBM-DDGS.

Other excellent references for DDGS are found on the following webpages:

Shurson, University of Minnesota https://www.ddgs.umn.edu/

Thaler, South Dakota State University https://ars.sdstate.edu/SwineExt/ddgs.htm

Conclusion

DDGS is a co-product from the ethanol industry and is a source of amino acids energy, and phosphorus

for swine. Producers must be aware of the wide variation of nutrients between different loads of

DDGS, and potential mycotoxin problems associated with DDGS. However, a proper analysis or

screening program can alleviate those concerns. Since DDGS is a poorer quality protein source than

SBM, the diets must be balanced on digestible amino acids and phosphorus. Also, no more than

20% DDGS should be used in grow-finish diets to avoid soft bellies. Once that is done, the decision

to use DDGS or not should be strictly based on economics.

South Dakota State University

USA

Tags · Benefits And Limitation Of DDGS For Swine

This article hasn't been commented yet.

Write a comment

* = required field